We have a specialised mixing business built upon supplying a number of close and loyal customers.

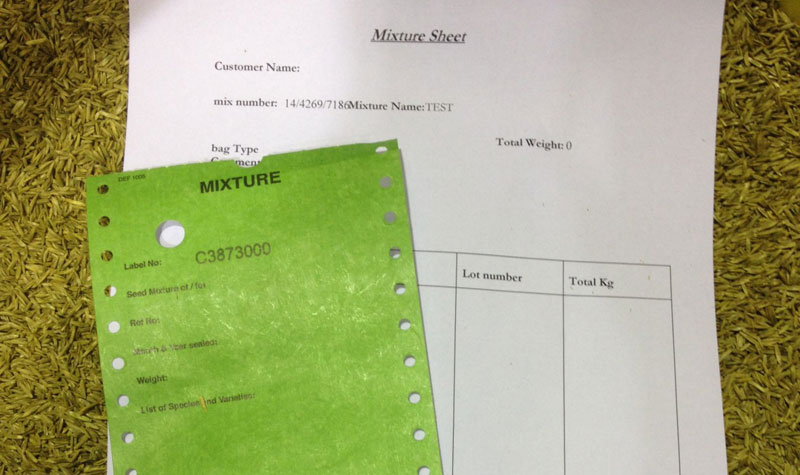

We act as a production unit for these customers and endeavour to have, and maintain, long term relationships with them. To comply with mixing regulations we must hold a license (supplied by DEFRA) and hold records of seed intake and straight ingredients used in each mix. We also have a unique packing number that is recorded on the mix label and on our seed mixture system. Every seed mixing company will also have a number unique to them. This enables DEFRA to locate where each mix originated from. The packing number is displayed as firstly the year, then the number relating to individual mix, then 7186 (our unique mixing plant number). Traceability is very important if there is ever any problem with the mix. Each label is supplied to us with a sequential number that is unique to the label. This is so all labels can be accounted for (even waste labels must be recorded).

Our bespoke computer system enables us to do the following:

- Add stock

- Create a mixture sheet

- When the mixture sheet is saved, the system automatically prints a mixture sheet and the green Defra labels

- The stock on the system is automatically updated

Good record keeping allows us to link all paperwork and track any problems quickly.

This system has enabled us to increase our volume output.

The Mixture Process

- Mixture sheet and labels are given to the warehouse staff.

- All the ingredients for the mix are collected and put into the mixer.

- Once all the ingredients are in the mixer, it is left for a while to ensure thorough mixing takes place and then a small amount is taken out into a clean bucket to check the seed is sufficiently mixed.

- The seed is then bagged off, weighed and adjusted to the correct weight.

- The bag is stitched together with a DEFRA green label attached.

- The warehouse staff check the stitching is secure and then place the bag on the pallet.

- Before wrapping the pallet, they double check the number of bags.

- The pallet is wrapped and labelled ready to be loaded onto the hauliers lorry.

- All our mixers are cleaned out after each mix to ensure there is no contamination.